Click here to see other posts about XRD

The fee of the quantitative Rietveld analysis using MAUD software depends on the XRD pattern complexity Payment Upon Completion Send your patterns...

1. Introduction

Today several instruments for fast spectra recording are available. In most cases the difficulty

is to process and analyze the data quickly in a reliable way. The Maud program, in one of its

many undocumented features, can be used to process a list of analyses in batch mode from the

console without requiring the interface. This is useful to process quickly similar spectra or launch

a slow/time consuming refinement in a remote computer without recurring to the interface that

would need to open a session involving the remote display setting.

The overall procedure is to prepare the analysis locally using the interface or to prepare a starting point for a series of spectra

(one common starting point) also using the interface, then to prepare an instruction file in CIF like

format to specify the analyses, the spectra and the kind of refinement to conduct and finally to run

Maud in batch mode providing the instruction file previously prepared. The program will run and

process one analysis at time and prepare an output file extracting some key information (either the

default or some to be specified) in a format suitable to be imported in spreadsheet or graphical

programs to analyze the results.

As an example we will show the procedure to analyze a series of ball milled Cu-Fe mixed powders

in which two different phases may form with a different composition. By an automatic Rietveld

analysis performed in batch mode we will extract information about phase content [2, 1], crystallite

and microstrain for each sample/spectrum. The analysis is further complicated from the fact that

the powders milled at higher energy show the presence of planar defects [5] and texture arising

from sample preparation and the platelet like shape of the grains [3].

2 Analysis and procedure

In this section we will present the procedure to analyze 25 spectra of Cu-Fe different samples. The

spectra has been collected by a Philips X-pert system in Le Mans at the LPEC laboratory of the

1

University du Maine, thanks to A. Gibaud.

2.1 Analysis preparation through the interface

We start the Maud program and load all the datafiles together to check their integrity and to prepare

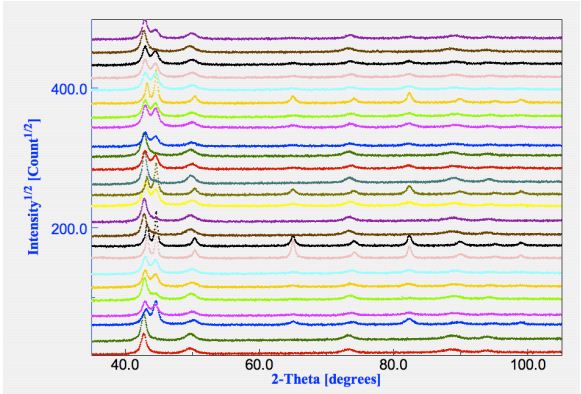

a common starting analysis file. A plot of all spectra and their differences is available in Figure 1.

presence of both fcc and bcc phases, but not in all.

We load the two possible phases, bcc iron and fcc copper, from the Maud database. By computing

the spectra once and comparing them visually with the experimental spectra we may notice that

for some samples, milled at longer time, an alloyed fcc phase form (out of equilibrium) and the

bcc iron disappears. Unluckily we could not use the copper rich phase cell parameter to monitor

the Fe content in it as the cell parameter tends to growth as a result probably of oxygen entrapping.

In a first attempt we discovered the spectra were affected by texture, anisotropic crystallite sizes

and microstrain as well as planar defects (especially on the Cu like phase). So we decide here

to include also texture and anisotropic/planar defects effects in the analysis. For both the bcc

and fcc phases we select in the proper panel the Popa model for anisotropic broadening [4], the

Warren model for planar defects and the harmonic model for texture (specifying cylindrical sample

symmetry and Lmax = 6 in the options; it is required by the experiment geometry).

Next step was to adjust the cell parameters for both bcc and fcc phases in order to get a mean

starting value good for all spectra (especially for the fcc); and to adjust the crystallite value to a

good starting point (around 200 angstrom) obtaining peak shapes a little sharper than in the less

broadened spectrum. The background constant parameter was also adjusted to the value of the

spectrum with the lower background. Actually only the cell parameter adjustment is critical, the

background one is even not necessary.

Finally we remove all the spectra (we will specify which datafile to use for each analysis later in an

instruction file) and save the analysis containing everything except the spectrum/a. For the purpose

of this article we save the analysis with the name: FeCustart.par.

2.2 Preparation of the instruction file and batch processing

To run Maud in batch we need to write an instruction file containing the list of analyses to execute

one at time. The file is in CIF format but containing some terms not available in the official CIF

dictionary, but that Maud recognize. All the analyses to be performed are specified through the

loop CIF instruction. The first term of the loop must be the one specifying the starting analysis

file to be loaded (full path in unix convention) and then the others to instruct Maud for the kind

of analysis to perform, iterations and eventually datafile to load and name of the file were to save

the analysis. Additional keywords can be used to append specific results to a file for spreadsheet

analysis. The simplest instruction file is something containing the following:

First example (paths for windows):

loop

riet analysis file

riet analysis iteration number

2

´//C:/mypathfortheanalysis/analysis1.par´ 5

´//C:/mypathfortheanalysis/analysis2.par´ 3

´//C:/mypathfortheanalysis/analysis3.par´ 7

The analysis1.par (or 2 or 3) are some analyses files prepared with Maud, containing also

the datafile/spectrum, already set for the parameters to be refined and saved just ready for the refinement step. Maud will load each analysis, starts the refinement with the number of iterations

specified and save the analysis with the refined parameters under the same name. The analyses can

be loaded at end in Maud (with the interface) to see the result of the refinement.

In the case of the Cu-Fe we need to perform some more steps: first we start from one common analysis point (the FeCustart.par analysis file) but we want to specify different datafiles; second

we want to perform a full automatic analysis in which Maud performs different cycles deciding

which parameters to refine at each step and third we will specify the name of each analysis for the

saving process and a file name were to append some selected results in a tab/column format for

subsequent easy loading in a spreadsheet program.

Cu-Fe example:

loop

riet analysis file

riet analysis iteration number

riet analysis wizard index

riet analysis fileToSave

riet meas datafile name

riet append simple result to

´//mypath/FeCustart.par´ 7 13 ´//mypath/FECU1010.par´ ´//mypath/FECU1010.UDF´

´//mypath/FECUresults.txt´

´//mypath/FeCustart.par´ 7 13 ´//mypath/FECU1011.par´ ´//mypath/FECU1011.UDF´

´//mypath/FECUresults.txt´

…………(lines with all the other 23 datafiles omitted for brevity)

´//mypath/FeCustart.par´ 7 13 ´//mypath/FECU1038.par´ ´//mypath/FECU1038.UDF´

´//mypath/FECUresults.txt´

With this instruction file (that we save under the name: fecu.ins) we specify for example that

as a first analysis, Maud has to load the FeCustart.par file, then to load in the analysis the

FECU1010.UDF datafile, to perform the automatic analysis number 13 (in the wizard panel of

Maud the automatic analysis number 13 is the texture analysis; we need to refine also the texture

parameters along with phase analysis and microstructure) and to use 7 iterations for each cycle (the

texture automatic analysis is composed by 4 cycles) to ensure sufficient convergence. At the end

the analysis is saved with the name FECU1010.par and simple selected results will be appended

in the file FECUresults.txt. The simple results saved in the spreadsheet like file are some of

the most used parameters and results. It is possible to specify the parameters we want in output

using the CIF word riet append result to (in addition or as an alternative), but in the

preparation of the starting analysis file in the Maud interface, the parameters to be added to the

results must be specified by turning to true the switch in the output column of the parameter list

window or panel.

Now to run Maud in batch in the console (

where the Maud.jar is located the following:

DOS (everything in the same line): java -mx512M -cp

“Maud.jar;lib\miscLib.jar;lib\JSgInfo.jar;lib\jgaec.jar;lib\ij.jar”

it.unitn.ing.rista.MaudText -f fecu.ins

Unix (everything in the same line): java -mx512M -cp

Maud.jar:lib/miscLib.jar:lib/JSgInfo.jar:lib/jgaec.jar:lib/ij.jar

it.unitn.ing.rista.MaudText -f fecu.ins

For Mac OS X, it is advised to use the generic Unix Maud installation (or to change the path to

the jar files). Before to run Maud in batch mode it is important to run Maud interactive (with the

interface) at least once to create and extract the databases, examples and preferences folder.

2.3 Analysis of results

After running Maud in batch mode, we can check quickly the results by loading the results file

FECUresults.txt in a spreadsheet program. The results are arranged in rows and separated

by tabs. The first row contains the column titles, each subsequent row a different analysis. The

Rwp value for each analysis is reported in the second column and the biggest value found was

5.6% as an indication of the success of the analysis. As an example we report in Figure 2 the

graphical correlation of the copper-rich phase percentage and its mean crystallite value as found

in the analysis versus the sample number. The files and examples used in this articles will be

uploaded in a tutorial in the Maud web page along with some additional files with the batch mode

commands for an easier use.

obtained by the automatic batch mode analysis. The plot has been created from the results file

saved by Maud.

3 How to get Maud 2.0 and further informations

For this analysis we need Maud version 2.037 or later and it can be freely downloaded from the

Maud web page at http://www.ing.unitn.it/ maud for the preferred platform. There are two archives

for Windows and Mac OS X plus a generic unix version that can be used for Linux, Solaris or

every unix based system with a Java 2 virtual machine installed. The new version 2.0 has a new

interface focused on reducing the effort of a new user and simplifying the most common tasks.

Some particularity of the new version respect to the previous one are (most of them to provide

some useful routines for ab-initio structure solution):

• Different minimization/search algorithms selectable: Marquardt least squares, Evolutionary

algorithm, Simulated annealing, Metadynamic search algorithm. As an example the evolutionary algorithm can be used in the early steps of the refinement to select the proper starting

solution and the Marquardt to drive it to convergence.

4

• Possibility to use crystallites and microstrain distributions for peak shape description instead

of analytical fixed shape functions.

• Maximum Entropy Electron Map full pattern fitting. An electron map can be used for fitting

instead of atoms.

• Full pattern fitting by a list of peaks. Either an arbitrary list of peaks (each one with its own

position, intensity and shape), or simply a list of structure factors to be imported, instead of

a list of atoms.

• Indexing directly on the pattern, selecting the Le Bail fit and the evolutionary algorithm for

the cell search. This may be used to improve a difficult indexing or a partly done one.

• Introduction of fragments. So fragment search can be done directly on the pattern or on a

list of extracted structure factors.

• Energy minimization. At the moment only the simple repulsion energy is completed. Other

energy principles are under completition.

• Spectra integration from image plate or CCD transmission/reflection 2D images. Center,

tilting errors and distance from sample can be refined in the spectra fitting.

Bugs and errors should be reported to the author through the bug reporter web page; questions in

the Maud forum accessible from the Maud web page.

In a future article we will report the instructions on how to modify/extend the program by little Java programming or provide a new alternative model/plugin for the instrument or the structure/microstructure or datafiles importing.

References

[1] D. L. Bish and S. A. Howard. J. Appl. Cryst., 21, 86–91, 1988.

[2] R. J. Hill and C. J. Howard. J. Appl. Cryst., 20, 467–474, 1987.

[3] L. Lutterotti and S. Gialanella. Acta Mater., 46(1), 101–110, 1998.

[4] N. C. Popa. J. Appl. Cryst., 31, 176–180, 1998.

[5] B. E. Warren. X-ray Diffraction. Addison-Wesley, Reading, MA, 1969

Author: Luca Lutterotti

Dipartimento di Ingegneria dei Materiali e delle Tecnologie Industriali

Universita di Trento, 38050 Trento, Italy `

E-mail: Luca.Lutterotti@ing.unitn.it

WWW: http://www.ing.unitn.it/ maud

Hi

I want to determine the amount of Al in the mixture of Al & Al2O3. Could you help me?